There was a flurry of things that I got done before going to KY. I was taking the truck, so the first thing was to empty it out. So I turned the tractor into the worlds most expensive wheelbarrow.

Apparently that was too much weight though. I haven't dropped the snowblower off it yet, so there was more than enough counterweight, but it was more than the hydraulics could lift. Oops. It could still rotate though, just not lift, which was all I needed to dump it.

The truck is empty now though. I just put them in a pile over by the sawhorses.

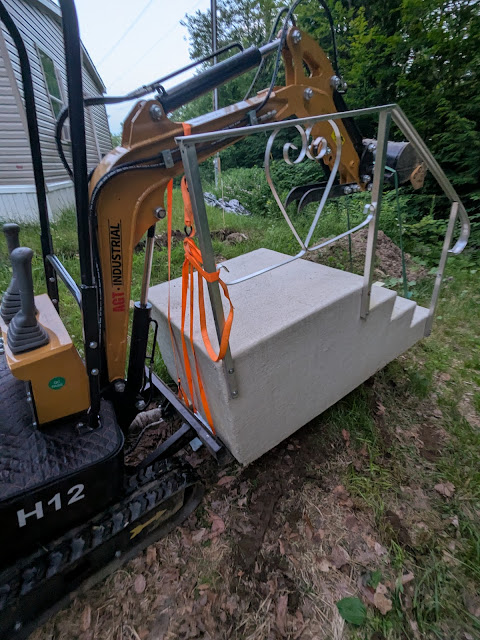

Then I had to get the steps into the truck. I haven't finished the drainage yet, so I used the excavator to get it to the ditch. It had no problems lifting it, though I would say they were near the weight limit. The hydraulics had plenty left, but if I leaned on the steps it would lift the back of the excavator, it needs more weight.

It did have problems balancing it though. The controls on the excavator are very jerky because it is cheap, and it was sliding around quite a bit and flopping to the side. I had to add more stability straps, which only sorta worked.

Sorta worked was enough though. From the ditch I could transfer it to the tractor, which holds it in the bucket a lot better.

I discovered something about the excavator while doing this: the weird intermittent electrical issues I have been having are because of the key. I got agitated when it wouldn't start, gave it some percussion maintenance, and discovered as long as I held the key down it worked fine. I switched to my other key and it also works fine. They are just cheap universal keys, so I might have to pick up another set, but at least I know the cause and won't have to tear apart the wiring harness which is a relief.

I was out of light by the time I got it to the ditch, so I started loading the truck instead. The big dresser was also going down.

The next morning before work I grabbed the tractor and finished the handoff. I should also note that the hydraulics on the excavator are now tight enough that it didn't completely drop overnight, which is a significant improvement. Funny how things work better when they don't leak...

The tractor is a lot more gentle and had no problems putting it in the truck, even as precarious as it was since I was lifting the light end and left the heavy end waay out.

My truck made the trip almost without issue. I had a TPMS sensor fail on the way down, which was really annoying because every time it tries to read the tire pressure (about once an hour or so) it dinged and brought up an error.

Despite the late start, I made it to Maryland before I stopped for work. It was miserably hot, and so humid that it was too hot to sleep despite me grabbing the fan I bought for the CR-V camper, so I didn't sleep long.

Since I naturally had to drive through some storms on the way down, I at least got to see a nice sunset afterwards.

I didn't have a ton of projects to work on while I was down in KY, so I mostly worked on the shed that I started last year. It still needs soffit wire and the trim pieces. I am regretting my decision at this point to build my own soffits instead of just buying one. They aren't that expensive; it would have cost twice what the wire did, but it is literally just screw it in and you are done. Oh well. I also installed some shelves and got my old tiny home dishwasher back up and running so my sisters have a dishwasher again.

We did get to try one of the things I picked up on my last trip. Cranberry maple syrup. It was surprisingly good. I got it on the Canadian side of Niagara Falls.

The drive home was a little bit cooler, so I slept better, but I did get to see some rather fearless trash pandas, errr, raccoons at one of the rest stops in West Virginia. They literally walked right up to me, and out in the lane of traffic. I expect they will be splat soon.

There was also a random cat on the prowl there as well.

I also noticed that the failure of the drip edges I bought online is now complete. One of the back ones has a clip failing, and the adhesive already failed. The front ones I had to rip off because they screwed up the sensors in the windows that detect whether there is an obstruction. It did make it home without completely falling out though, this picture was taken when I stopped for gas in Morehead in KY.

Everything was fine at home, other than I really need to make a run to the dump, I didn't have time before I left, and you could smell the bags outside if you are withing ten feet of the can. Apparently we lost power at some point while I was gone too, all the electric clocks like the one on the stove were way out of whack. It drizzled on me a little when I got home, but it looks like the bulk of the rain has been taken out of the forecast for the next day or two, so there is still a chance it will stay dry enough for me to finish the drainage pipe. Getting rid of the steps wasn't on the list, but it is now complete, and my sisters now have nice stairs at their back door as well.

Available Projects and annual tasks:

- Dunks and bug repellent.

- Clean up yard

- Take scrap metal away

- Finish cleanup on the pile in the back

- Do something with the trailer.

Fix excavator- Finish drainage

- Build deck

- Push back trees

- Install concrete pilings

- Install landscape fabric and gravel underneath

- Build frame

- Lay decking

- Set up hot tub and pool

- Build insulated platform for hot tub

- Put down pool sand to level spot for pool

- Get water delivered for both

Fix mowers and equipment- Get tractor serviced

- Build travel station for CR-V/prep CR-V for travel

- Move carport

- Build the roof extension over to the rocks

- Fix front stairs

- Test travel options (rent u-haul and test that, rent trailer and test that)

- Install storm doors

- Build overhangs for windows

- Insulate the water lines

- Front yard drainage

- Fix snowblowers (broken grease fitting on big snowblower, gas leak on small one)

- Gravel/hardpack driveway

- Fix grade to the shed

- Level a spot for a lean-to up the hill

- Build a small lean-to for off-season equipment

- Make shed mouse-tight

- Create walking trails (put up markers, maybe put down some gravel).

- Clear and level a spot for orchard

- Build a bridge over the creek

- Build a gazebo or something on the other side